What Pressure Range Should I Choose?

What Does It Mean?

2-32 psi means that as long as the difference in pressure between the two ports on the valve is greater than 2 psi and less than 32 psi, the flow will be within 5% of the rated flow. It’s important to note that it’s the difference that matters: if the red port is at a gauge pressure of 312 and the blue port is at 300, the flow will be exactly the same as if they were 62 and 50 respectively. The port nearest the inlet should have the red strap and should have the higher pressure.

A Little Background

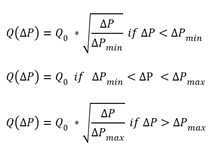

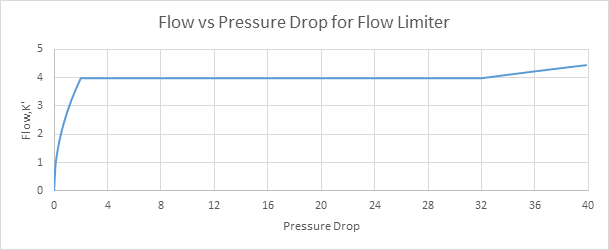

A flow limiter is a device which normally has a fixed resistance up to some starting pressure, and thereafter changes resistance as needed to maintain a constant flow until a maximum pressure is reached, after which the flow is again like a fixed resistance.

So What Range Should I Choose?

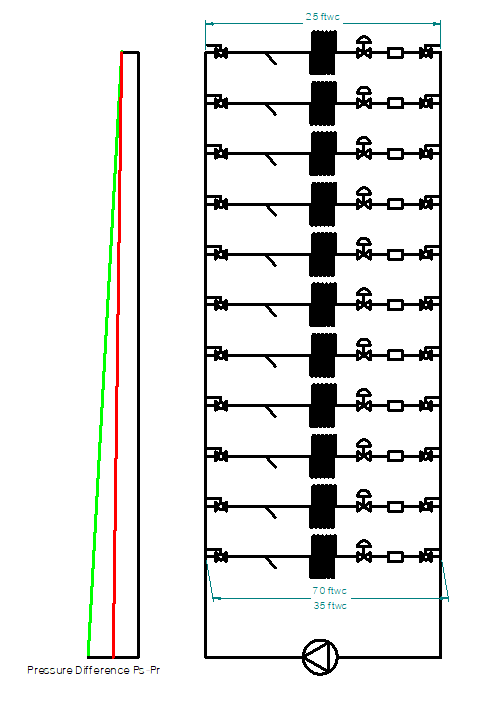

It’s important to note that after the maximum regulated pressure the flow goes up proportionally to the square root of the pressure difference. Thus at 10% more pressure the flow will only have increased about 5%, and at 20% more pressure only about 10%. Thus it’s normally OK to use the 3-32 pressure range up to around 40 psi. If the pump pressure is over 40 psi, then probably it’s still possible to use 2-32 for most of the system, with 5-60 only being used at the terminals nearest to the pump. To actually figure out how near the pump requires knowing the pressure losses in the headers. With variable speed systems using Autoflow, it’s common to place the sensor for controlling the pump across the index circuit (the circuit with the least surplus pressure differential), so the pressure difference across any circuit in the building will never go higher than at maximum load. Thus if we take the pressure supplied by the pump and subtract the losses in the main piping until it reaches 40 psi, that’s where we would switch from the 5-60 range to the 2-32 range.

Just to clarify about the illustration, it’s an over-simplified building showing one terminal per branch. The graph on the left is the pressure difference between the supply and return headers shown as the distance between the green or red line and the black line at any point along the building. The green line represents maximum load, and the red line represents a reduced load with about 40% of maximum for the total flow (perhaps 70% thermal load).