Venturi Balancing Valves

IMI Flow Design sells manual balancing valves based on a fixed venturi element. This brings up certain questions, of course.

What’s a Venturi?

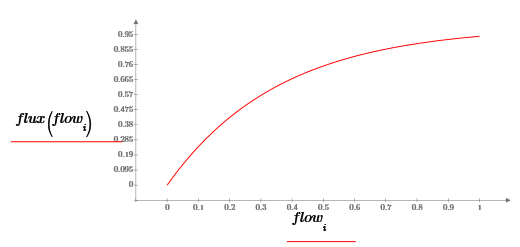

A venturi, at least in this context, is a device which converts pressure to kinetic energy, then converts it back.

To put it simply, it gets narrow, then widens out gradually so as not to stir the water up too much. As the passage narrows, the pressure goes down. That might sound confusing, but the fluid has to speed up and it only does that when there’s more pressure behind it than in front of it. As the passage gradually widens, the pressure increases again. That might also seem confusing, but the fluid will be slowed down by some combination of friction with the wall and increasing pressure: if we avoid too much stirring and make the passage smooth, most of the slowing down will be from increasing pressure.

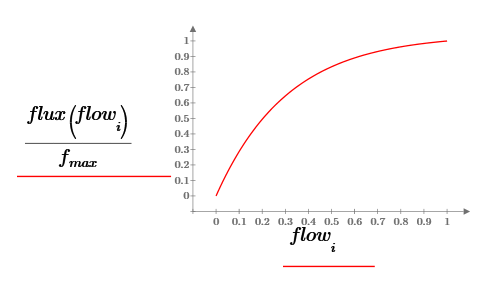

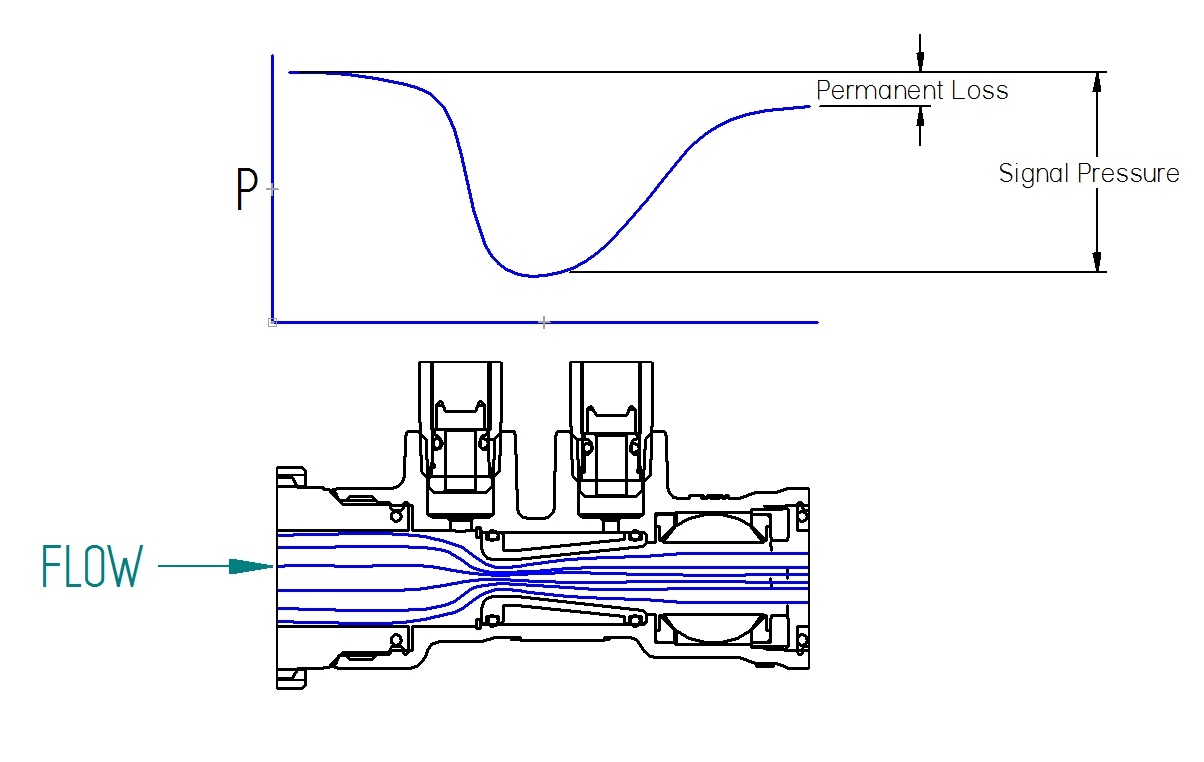

For a flow meter, we have a connection to the water stream before the passage narrows, and a second port at the narrowest point which we sometimes call the “throat”. The pressure at the throat is lower than the downstream pressure, so the pressure difference we read is higher than the permanent loss that’s created. That last sentence is the whole point. Figure 1 shows how the pressure changes as water flows through a venturi. On top is a graph of pressure, and below is a cross-section showing streamlines.

Why Use a Venturi?

- Because it conditions the flow, a venturi is less sensitive to upstream and downstream conditions than a simple orifice.

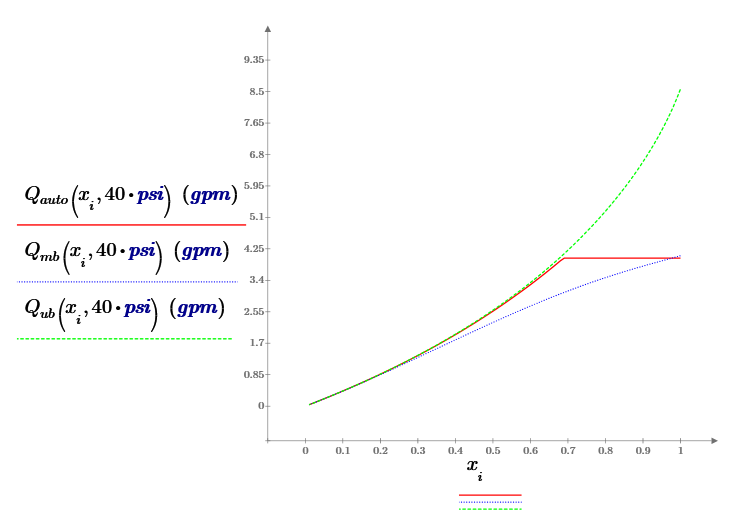

- The signal pressure on a venturi is higher than the permanent loss. Whatever signal the balancing company considers acceptable, the pumping loss will be lower with a venturi than with a non-recovering flow restriction.

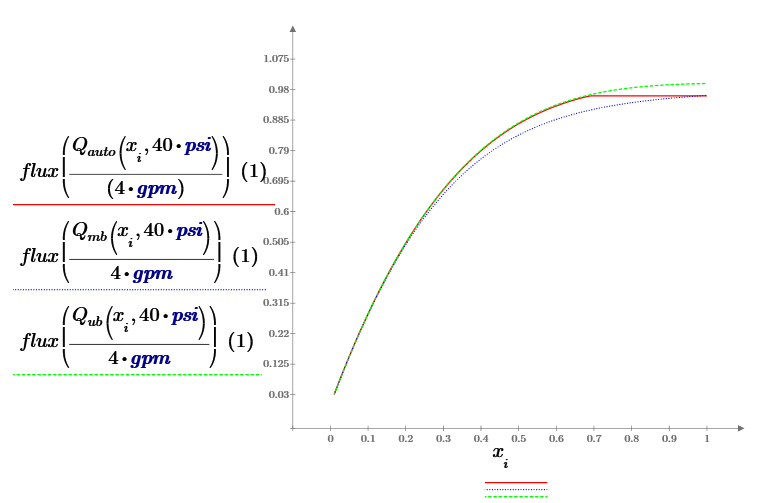

- IMI Flow Design’s venturis have been tested to ensure that at any given flow rate the pressure signal is the same regardless where the balancing valve handle is set: so just find the target pressure and dial it in.

- IMI Flow Design’s venturis are accurate within 3% or better. This kind of accuracy comes from a simple geometry made with CNC machinery. Most other kinds of differential pressure flow meters are less accurate because they depend on too many variables.