Dual Seal End Pieces

Motivation

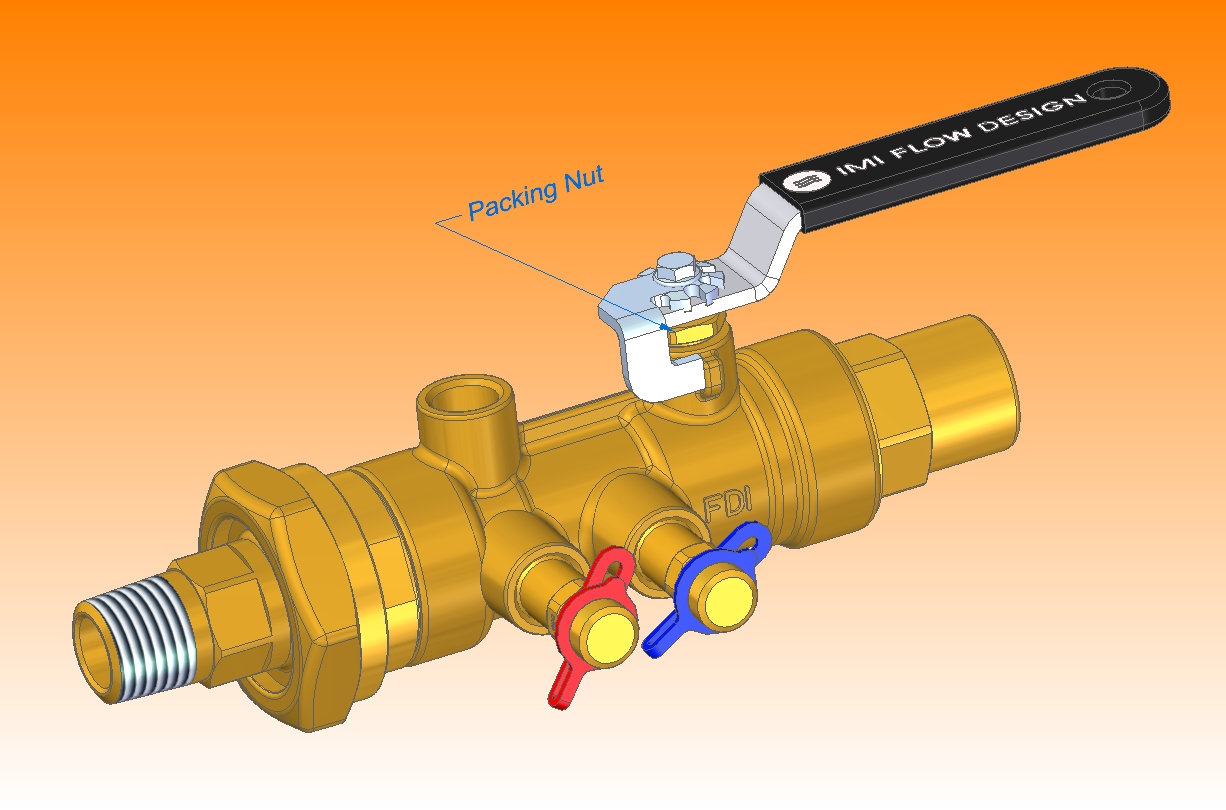

For years, IMI-Flow Design has provided valves with end connections customized for the job at hand. When field disconnection is desired this means our carefully designed o-ring unions with their superior o-ring retention, but on system connections for an isolation valve a more permanent and tamper-proof system is required.

The dual seal end-piece design is a permanent connection which is far more reliable than other systems. While allowing IMI-Flow Design to customize valves readily, it provides redundant sealing mechanisms which make a leak nearly impossible.

What It Is

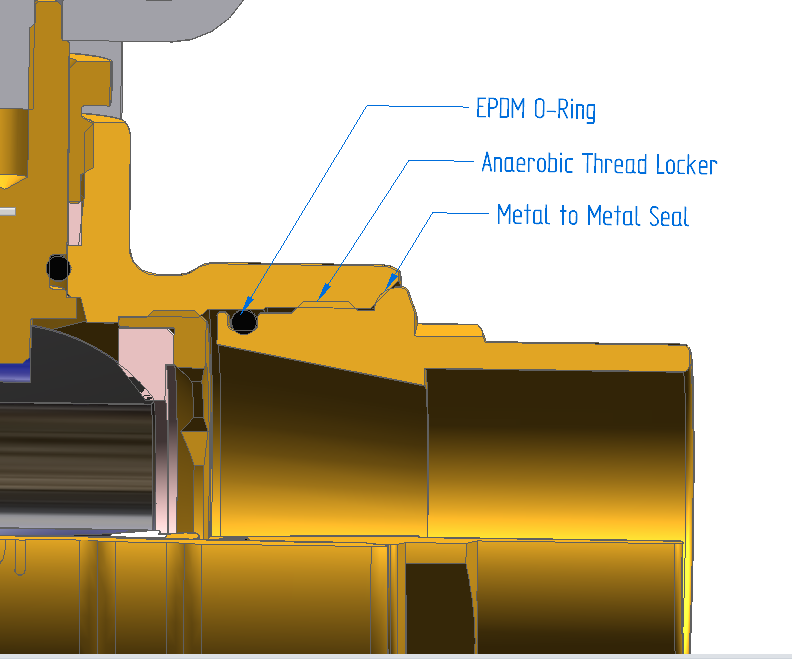

Beginning with the Unibody Accusetter (UA) and Unibody Ball Valve (UB) in 2002, IMI-Flow Design has offered a new style of end-piece. Since then, the design has proven highly reliable on more than a million units installed. It uses a metal to metal seal outboard of the connecting threads, which is almost completely immune to heat. An anaerobic thread locker keeps the end-piece from being loosened in order to ensure the pressure on this metal-to-metal seal. Inboard of the connecting threads, where the probability of heat damage is minimized, is an EPDM O-ring. EPDM was selected due to its excellent performance in aqueous environments and its excellent resistance to compression set.

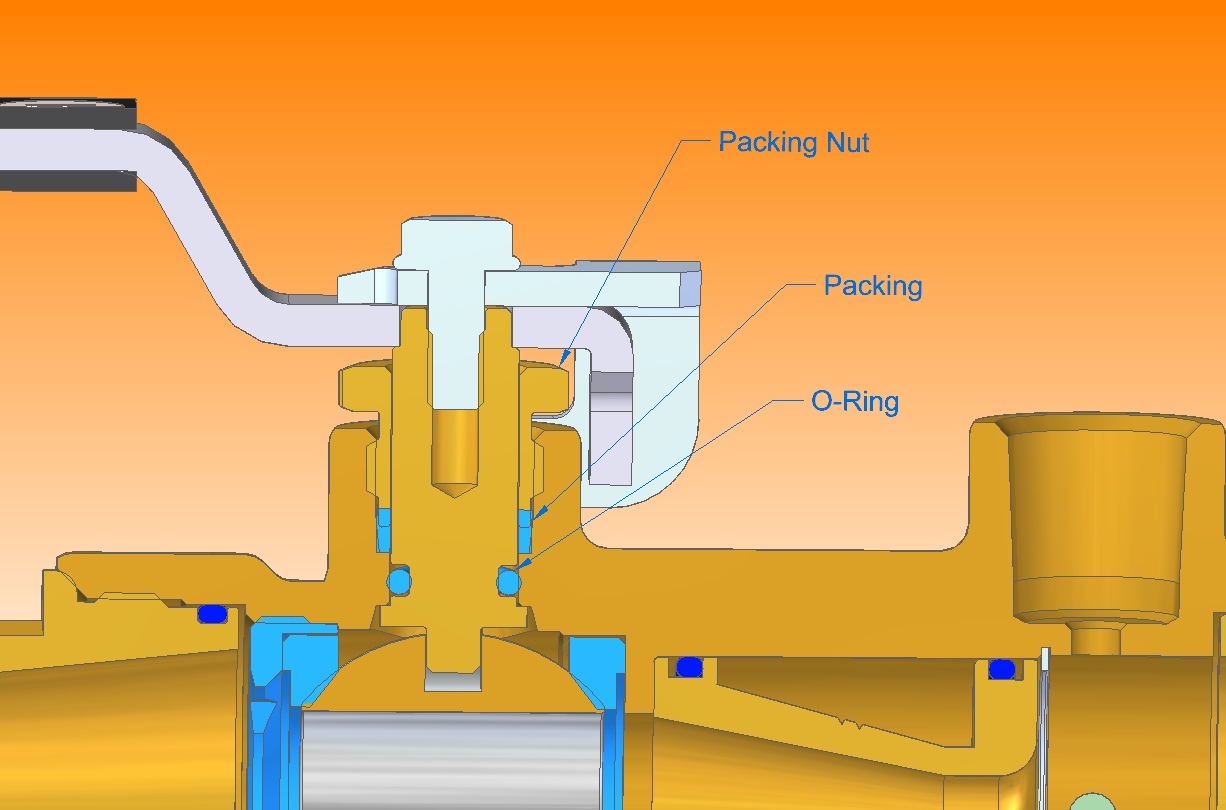

Also visible in the figure is the retaining nut for the ball valve. By setting the compression on the ball valve seats separately from the torque on the end-piece, IMI-Flow Design is able to ensure that each is appropriate for its purpose: other designs can potentially require a compromise to seat tension or worse still inadequate torque on the body’s sealing surfaces.

Bottom Line

IMI Flow Design can provide valves with the right ends to prevent the need for field-installed adapters. These ends will be installed at the factory and include exclusive and extremely reliable sealing systems. The net effect is less effort and fewer worries for the installer.