VersaFlow Hose Kit Assemblies

Regardless of balancing method selected, all kits have valuable common features on which most designers and owners can agree.

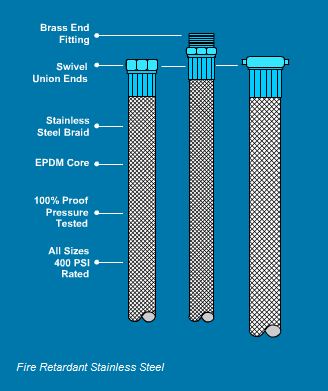

Each assembled hose is individually tested hydro-statically for leak and mechanical integrity.

The entire F.D.I. line of hose products (1/2″ thru 2″) is rated 400 WPSI. These high strength products no longer make the hose the weak link in a piping system.

EPDM was chosen as the core for the F.D.I. hose products because of it’s superior qualities of strength, high temperature limitations, flexibility, memory and resistivity to chemical additives found in HVAC systems.

Swivel ends minimize installation time and allow “looping” for initial flushing and draining of piping systems.

Stainless steel braid offers excellent tensile strength, resistance to corrosion, consistent strand diameter and braidability. The proper pick and braid angle of stainless steel strand yields the highest strength, flexibility and percent of core coverage.

All fittings are manufactured from 360 brass, maintaining excellent machinability and close tolerances. Consistency in threads (NPTF) and repeatability of fitting barb dimensions (<0.002″) assure uniformity throughout the product line. 360 brass also minimizes the possibility of electrolytic action.

Each assembly is proof pressure tested to 600 PSI in accordance with the Rubber Manufacturers Association which precludes faulty products from being installed.